Why Bimetallic Lugs Are Essential for Modern Electrical Systems

Bimetallic lugs play a crucial role in the efficiency and safety of modern electrical systems. Their unique construction allows them to connect different types of conductors, specifically copper and aluminum, which is essential in a variety of electrical installations.

The Role of Bimetallic Lugs in Electrical Installations

How to Choose the Right Bimetallic Lugs for Your Projects

Advantages of Partnering with a Bimetallic Lugs Supplier

Innovations in Bimetallic Lugs Technology

Best Practices for Installing Bimetallic Lugs

The Role of Bimetallic Lugs in Electrical Installations

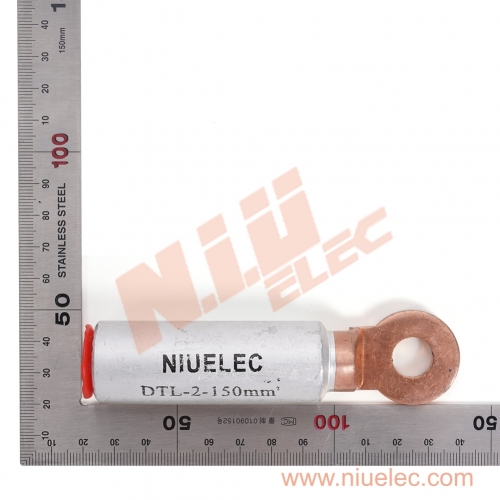

Our bimetallic cable connectors ensure a reliable connection between aluminum conductors and copper busbars or terminals, preventing galvanic corrosion and enhancing safety. Ideal for power distribution systems, industrial machinery, and residential wiring, these connectors provide stability and efficiency. Choose our high-quality bimetallic cable connectors for your electrical needs.

Ensuring a secure and reliable connection in electrical systems is paramount, and bimetallic lugs excel in this aspect. Their design minimizes electrical resistance and heat generation at the connection point, ensuring long-term performance and safety. This makes them indispensable in high-load environments where reliability is non-negotiable.

How to Choose the Right Bimetallic Lugs for Your Projects

Selecting the right bimetallic lugs for your projects involves considering several factors, including the type of conductors, load requirements, and environmental conditions. It's essential to choose lugs that are compatible with the specific cable sizes and materials used in your installation. Additionally, the lug should be rated for the electrical load it will carry, ensuring it can handle the current without overheating or failing.

When selecting bimetallic lugs, it's also important to consider the operating environment. For instance, installations in corrosive or high-moisture environments require lugs with protective coatings to prevent degradation over time. Consulting with a trusted supplier can provide valuable insights and recommendations tailored to your specific needs.

Advantages of Partnering with a Bimetallic Lugs Supplier

Partnering with a reputable bimetallic lugs supplier offers numerous advantages. A reliable supplier ensures consistent product quality, essential for maintaining the integrity of your electrical installations. Quality bimetallic lugs undergo rigorous testing to meet industry standards, guaranteeing their performance and durability.

Furthermore, a good supplier provides technical support and expertise, helping you choose the right products for your applications. They can offer guidance on installation best practices and troubleshooting, ensuring that your projects run smoothly from start to finish. Building a long-term relationship with a trusted supplier can also lead to cost savings through bulk purchasing and ongoing support.

Innovations in Bimetallic Lugs Technology

The field of bimetallic lugs technology is continuously evolving, with innovations aimed at improving performance, safety, and ease of installation. Recent advancements include the development of lugs with enhanced corrosion resistance, improved thermal conductivity, and more efficient crimping mechanisms. These innovations contribute to longer service life and better overall performance of electrical systems.

Manufacturers are also incorporating advanced materials and coatings to enhance the durability and reliability of bimetallic lugs. For example, some lugs now feature nano-coatings that offer superior protection against environmental factors. These technological advancements ensure that bimetallic lugs remain at the forefront of electrical connectivity solutions.

Best Practices for Installing Bimetallic Lugs

Proper installation of bimetallic lugs is critical to ensuring their effectiveness and longevity. Start by thoroughly cleaning the conductors to remove any oxidation or contaminants that could impair the connection. Use the appropriate crimping tool to apply uniform pressure, ensuring a secure and reliable connection. Follow the manufacturer's guidelines for crimping force and technique to avoid damaging the lug or the conductor.

It's also essential to inspect the connection regularly as part of routine maintenance. Look for signs of wear, corrosion, or overheating and address any issues promptly. Properly installed and maintained bimetallic lugs will provide years of reliable service, safeguarding your electrical systems and preventing costly downtime.

In conclusion, bimetallic lugs are essential components in modern electrical systems, offering reliable connections between different types of conductors. By choosing the right lugs, partnering with reputable suppliers, staying abreast of technological advancements, and following best installation practices, you can ensure the efficiency and safety of your electrical installations. For more information on high-quality bimetallic lugs, visit Niuelec. Learn more and get started with the best in electrical connectivity solutions.