How the Right Parallel Groove Clamps Can Drive Eco-friendly Construction Solutions

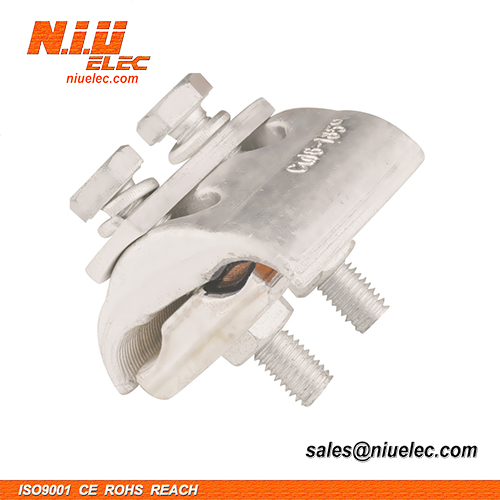

In today’s rapidly evolving industrial landscape, sustainability is no longer a trend—it is a necessity. Industries across the board are under increasing pressure to adopt environmentally friendly practices that reduce their carbon footprint and conserve valuable resources. For manufacturers of industrial components, like Parallel Groove Clamps, the opportunity to play a pivotal role in this green revolution is significant.Parallel Groove Clamps are widely used in the electrical and telecommunications industries to secure conductors, ensuring the integrity and safety of critical infrastructure systems. However, the materials used in the manufacturing of these clamps can have a substantial environmental impact. As sustainability becomes a priority for consumers, contractors, and government bodies alike, manufacturers must rethink their material choices, manufacturing processes, and the overall lifecycle of their products.In this article, we’ll explore how adopting eco-conscious material sourcing and manufacturing practices in the production of Parallel Groove Clamps can not only reduce environmental harm but also provide long-term benefits to manufacturers and end-users. By focusing on the six critical elements of sustainability in materials selection, manufacturers can align themselves with the growing demand for eco-friendly products while gaining a competitive edge in the market.

Table of contents:

The Importance of Material Sourcing: A Sustainable Supply Chain

Environmental Impact of Material Production: Reducing Carbon Footprint

Material Durability: Less Waste, Longer Lifespan

Environmentally Friendly Surface Treatment: Sustainable Finishes

Certification and Compliance: Ensuring Eco-Conscious Standards

Product Lifecycle: Minimizing Waste from Production to Disposal

The Importance of Material Sourcing: A Sustainable Supply Chain

One of the first steps in creating an environmentally responsible product is selecting the right raw materials. For Parallel Groove Clamps, aluminum is the most commonly used material, but the sourcing of aluminum is crucial when it comes to environmental sustainability.

Recycled Aluminum: The production of Parallel Groove Clamps from recycled aluminum significantly reduces the environmental impact compared to using virgin aluminum. Aluminum recycling requires up to 95% less energy than producing new aluminum from bauxite ore. This not only conserves energy but also reduces harmful emissions, including greenhouse gases. Moreover, the use of recycled aluminum reduces the need for mining, which is often linked to deforestation, habitat destruction, and soil erosion.

Ethical Sourcing: Another important factor in sustainable material sourcing is ensuring that aluminum is sourced from responsible and ethical suppliers. The mining and extraction of bauxite, the primary ore used to produce aluminum, can have significant environmental consequences, including deforestation, water pollution, and soil degradation. Manufacturers should work closely with suppliers who follow sustainable mining practices and adhere to strict environmental and social standards.

Certifications and Standards: Certifications like the Aluminum Stewardship Initiative (ASI) ensure that the material sourced for Parallel Groove Clamps meets high environmental and ethical standards. By choosing certified aluminum, manufacturers ensure that their products contribute to responsible sourcing and meet international environmental expectations.

By prioritizing sustainable sourcing, manufacturers can create products that align with the growing trend toward corporate responsibility and environmental stewardship. This commitment to sustainability resonates with increasingly eco-conscious consumers and businesses looking for greener alternatives in their construction and infrastructure projects.

Environmental Impact of Material Production: Reducing Carbon Footprint

Once the material is sourced, the next critical stage is the production process. The environmental impact of manufacturing Parallel Groove Clamps depends largely on how the raw materials are processed and the energy used in the production.Energy-Efficient Production: The production of aluminum and other metals traditionally requires large amounts of energy, most of which comes from fossil fuels. However, several aluminum manufacturers are now adopting cleaner, more sustainable practices. For instance, using renewable energy sources such as solar or wind to power smelting plants significantly reduces the carbon footprint of the material production process. By sourcing aluminum from suppliers that use renewable energy, Parallel Groove Clamp manufacturers can dramatically cut their environmental impact.

Advanced Production Technologies: In addition to using renewable energy, adopting more energy-efficient production techniques is key. Modern smelting technologies, such as the use of inert anodes, significantly reduce the emission of greenhouse gases, particularly carbon dioxide, which is a major contributor to climate change. Manufacturers who prioritize these technologies ensure that their products are created with the least environmental impact possible.

Waste Minimization: The production of Parallel Groove Clamps also generates waste, particularly scrap metal. By adopting closed-loop recycling processes, manufacturers can recycle scrap metal back into the production process, reducing waste and conserving valuable resources. This practice not only minimizes the environmental impact but also lowers manufacturing costs by reducing the need for new materials.

Incorporating energy-efficient production methods and advanced technologies not only reduces carbon emissions but also lowers production costs in the long run, offering a clear financial incentive for manufacturers to invest in greener practices.

Material Durability: Less Waste, Longer Lifespan

Durability is a key aspect of product sustainability. A product that is durable and requires minimal maintenance reduces the need for frequent replacements, conserving resources and reducing waste.

Corrosion-Resistant Materials: Parallel Groove Clamps are often used in outdoor or harsh environments, where exposure to moisture, chemicals, and extreme temperatures can lead to wear and corrosion. Aluminum, known for its natural resistance to corrosion, is an ideal choice. Manufacturers can further enhance durability by selecting high-quality alloys that offer increased strength and resistance to environmental stressors.

Long Product Lifespan: The longer the product lasts, the less often it needs to be replaced, which directly impacts waste reduction. By designing Parallel Groove Clamps to withstand wear and tear over time, manufacturers contribute to a more sustainable lifecycle. For instance, clamps with better resistance to corrosion will last longer in demanding environments, meaning fewer replacements are necessary, thus reducing the overall consumption of resources.

Maintenance and Repair: Another consideration is the ease of maintenance. Parallel Groove Clamps that are designed for easy repair or adjustment can help extend their useful life. Products that require less frequent servicing or replacement not only reduce costs but also lessen the overall environmental impact by minimizing the resources needed for production and disposal.

Long-lasting, durable products are a cornerstone of sustainability, as they reduce the demand for new materials and lower the volume of waste generated over time.

Environmentally Friendly Surface Treatment: Sustainable Finishes

Surface treatments are often used to enhance the appearance of Parallel Groove Clamps and improve their performance in challenging environments. However, traditional surface treatments can be harmful to the environment due to the chemicals and processes involved.

Eco-Friendly Surface Treatments: Instead of using toxic chemicals like chromium or solvents in traditional anodizing or plating processes, manufacturers can opt for non-toxic, environmentally friendly alternatives. Anodizing aluminum using organic acids and water-based solutions reduces harmful chemical runoff and makes the product safer for workers and the environment.

Powder Coating: Another eco-friendly surface treatment is powder coating. Unlike traditional liquid paints, powder coating does not require solvents and has minimal volatile organic compound (VOC) emissions. This makes it a cleaner, safer option for both the environment and factory workers.

Non-Toxic Sealants: Using environmentally safe sealants and coatings helps improve the longevity of Parallel Groove Clamps while ensuring that no harmful chemicals are released into the environment. These non-toxic treatments not only protect the product from corrosion and wear but also ensure that the product meets environmental standards.

By adopting environmentally friendly surface treatments, manufacturers can significantly reduce the environmental impact of their Parallel Groove Clamps, all while improving the overall quality and durability of the product.

Certification and Compliance: Ensuring Eco-Conscious Standards

As environmental regulations become more stringent, certifications and compliance with international environmental standards are vital. Parallel Groove Clamp manufacturers who earn certifications demonstrate their commitment to sustainable practices and meet the growing demand for eco-friendly products.

ISO 14001: This international standard for environmental management ensures that a company adheres to best practices in reducing environmental impact. Manufacturers that comply with ISO 14001 can prove to their customers that they are committed to minimizing their ecological footprint.

Cradle to Cradle: This certification evaluates the sustainability of a product throughout its lifecycle, from sourcing to disposal. Products that earn Cradle to Cradle certification are designed with circularity in mind, ensuring that materials can be reused or safely returned to the environment.

RoHS and REACH Compliance: The RoHS Directive (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) are European Union standards that regulate the use of hazardous materials in products. Parallel Groove Clamps manufacturers should ensure that their products comply with these regulations, which guarantee that harmful substances like lead and cadmium are not present in the final product.

Eco-Labels: Many eco-labels and certifications are recognized worldwide as symbols of sustainable practices. Obtaining these certifications can enhance a manufacturer’s reputation and appeal to eco-conscious customers.

Product Lifecycle: Minimizing Waste from Production to Disposal

A truly sustainable product is one that considers its entire lifecycle, from raw material extraction to eventual disposal.

Recyclability: Aluminum, being a highly recyclable material, can be easily repurposed into new products at the end of a Parallel Groove Clamp’s life. By designing clamps that are easy to disassemble and recycle, manufacturers can ensure that the product has a minimal impact on landfills.

Modular Design: Modular designs allow for the easy replacement of individual components rather than entire products. This reduces waste and encourages the reuse of parts that are still functional. For example, replacing just the securing mechanism of a Parallel Groove Clamp instead of the whole unit prevents the disposal of usable components.

Sustainable Packaging: Manufacturers can reduce their environmental footprint by using recyclable or biodegradable packaging materials. Lightweight packaging that minimizes space and weight can also reduce transportation-related emissions.

The push toward sustainability is not just a passing trend—it is a shift in the way industries operate. As environmental concerns grow, the demand for Parallel Groove Clamps made from sustainable materials and manufactured with eco-conscious processes will only increase.By focusing on responsible sourcing, energy-efficient production, durable materials, eco-friendly surface treatments, certifications, and full product lifecycle considerations, manufacturers can help drive the construction and infrastructure industries toward a greener future.Ultimately, those who invest in sustainability today will not only be contributing to a healthier planet but also ensuring their place as leaders in the eco-conscious marketplace. Companies like Niuelec, which are committed to sustainable practices, are leading the charge in this transformation, offering high-quality Parallel Groove Clamps that meet the demands of both the market and the planet.As the industry moves forward, the importance of choosing sustainable materials and adopting responsible manufacturing processes will continue to grow. By embracing these practices, manufacturers can create long-lasting, eco-friendly products that meet the needs of today’s environmentally conscious consumers and businesses.