By niuelec | 21 February 2025 | 0 Comments

The Role of Parallel Groove Clamps in Electrical Systems: A Comprehensive Guide

In the complex world of electrical systems, seemingly small components often play crucial roles in ensuring safety, reliability, and efficiency. Among these, the parallel groove clamp stands out as a fundamental connector for joining conductors in a variety of applications. As a leading parallel groove clamp manufacturer, we aim to provide a comprehensive understanding of these essential devices. This guide will explore what a parallel groove clamp is, how it works, the key differences between aluminium PG clamps and other connectors, and the industries that heavily rely on them for their electrical projects.

Table of contents:

What is a Parallel Groove Clamp and How Does it Work?

The Differences Between Aluminium PG Clamps and Other Electrical Connectors

Top Industries That Rely on Parallel Groove Clamps for Electrical Projects

What is a Parallel Groove Clamp and How Does it Work?

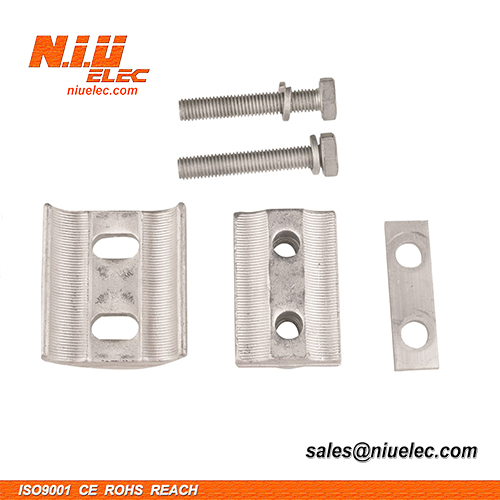

A parallel groove clamp (PG clamp) is a mechanical connector designed to join two parallel conductors securely and reliably. These clamps typically consist of two grooved plates, often made of aluminium alloy, that are bolted together to grip the conductors. The grooves are specifically designed to match the shape and size of the conductors, ensuring maximum contact area for efficient electrical conductivity. When the bolts are tightened, the clamp applies pressure evenly across the conductors, creating a strong mechanical and electrical connection. The design allows for easy installation and maintenance, making it a practical choice for various electrical applications.

The Differences Between Aluminium PG Clamps and Other Electrical Connectors

While several types of electrical connectors exist, aluminium PG clamps offer distinct advantages in specific scenarios. Unlike compression connectors, which require specialized tools and crimping, PG clamps can be installed with standard wrenches, simplifying the installation process. Compared to bolted connectors, PG clamps provide a more uniform pressure distribution, reducing the risk of localized stress on the conductors. Furthermore, the aluminium construction of aluminium PG clamps offers excellent corrosion resistance, making them ideal for outdoor applications where exposure to moisture and environmental elements is a concern. This durability sets them apart from connectors made of other materials, which may be more susceptible to degradation over time.

Top Industries That Rely on Parallel Groove Clamps for Electrical Projects

Parallel groove clamps are indispensable in numerous industries where reliable electrical connections are paramount. The power distribution sector relies heavily on PG clamps for connecting conductors in substations, transmission lines, and distribution networks. Telecommunications companies utilize them for grounding and bonding equipment, ensuring signal integrity and safety. The construction industry employs PG clamps in building electrical systems, connecting wires and cables for lighting, power outlets, and other electrical devices. Renewable energy projects, such as solar and wind farms, also depend on PG clamps for connecting conductors in the array wiring and grounding systems. The versatility and reliability of PG clamps make them an essential component in these diverse industries.

In conclusion, parallel groove clamps play a critical role in ensuring the integrity and efficiency of electrical systems across various sectors. Understanding their function, advantages over other connectors, and applications in different industries highlights their importance. Whether you're in power distribution, telecommunications, construction, or renewable energy, choosing the right aluminium PG clamp from a reputable parallel groove clamp manufacturer is crucial for maintaining safe and reliable electrical connections. Consider factors like conductor size, environmental conditions, and application requirements when selecting the appropriate PG clamp for your project.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES

TAGS