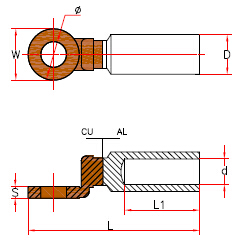

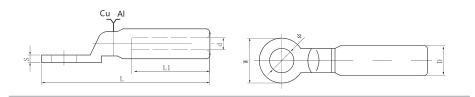

Application:

DTL-5 Forged Bimetallic Lugs are suitable for connecting ABC cables to transformers, switchgear etc. on the pole top.

Features:

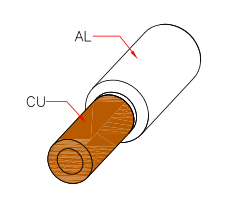

1. Friction welded.

2. Aluminium barrel is filled by neutral grease and covered by cap.

3. Material: CU≥99.9%, AL≥99.5%

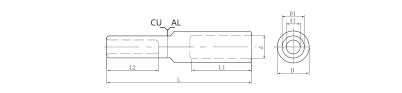

| Item No. | φ±0.3 | D±0.2 | d±0.2 | L±2 | L1±2 | W±0.2 | S±0.2 |

| DTL-5-16 | 10.5 | 16 | 5.5 | 80 | 40 | 20 | 4.0 |

| DTL-5-25 | 10.5 | 16 | 7.0 | 80 | 40 | 20 | 4.0 |

| DTL-5-35 | 10.5 | 16 | 8.2 | 80 | 40 | 20 | 4.0 |

| DTL-5-50 | 12.8 | 20 | 9.2 | 90 | 43 | 25 | 5.5 |

| DTL-5-70 | 12.8 | 20 | 11.2 | 90 | 43 | 25 | 5.5 |

| DTL-5-95 | 12.8 | 20 | 12.5 | 90 | 43 | 25 | 5.5 |

| DTL-5-120 | 12.8 | 25 | 14.0 | 112 | 58 | 30 | 6.5 |

| DTL-5-150 | 12.8 | 25 | 16.5 | 112 | 58 | 30 | 6.5 |

| DTL-5-185 | 12.8 | 32 | 18.5 | 122 | 60 | 35 | 7.0 |

| DTL-5-240 | 12.8 | 32 | 20.0 | 122 | 60 | 35 | 7.0 |

| DTL-5-300 | 12.8 | 34 | 23.5 | 125 | 65 | 35 | 7.0 |

| DTL-5-400 | 17.0 | 40 | 26.0 | 160 | 90 | 36 | 7.0 |

| DTL-5-500 | 17.0 | 40 | 29.5 | 160 | 90 | 36 | 7.0 |

Advantages:

1)Alternative sizes can be made to order for approved order quantities.

2)The technology of friction welding is wonderfully adopted. Cable lugs are fully annealed to guarantee optimum ductility.

3)Therefore they have distinguishing features of strong weld intensity, good nature in electrification resistant galvanic corrosion and long service life.

Instructions:

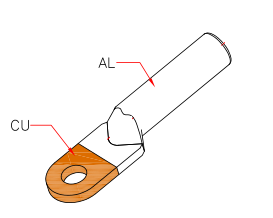

DTL-1 Cable Bimetallic Lugs are designed for connection of aluminum conductors to coppers busses, wires and cables in order to eliminate galvanic effect produced in results of direct connection copper and aluminum in the course of wiring and power load hookup.

| Item No. | φ | D | d | L | L1 | W | S |

| DTL-1-10 | 8.5 | 10 | 5.2 | 65 | 30 | 16 | 2.2 |

| DTL-1-16 | 8.5 | 11 | 6.1 | 70 | 31 | 16 | 2.2 |

| DTL-1-25 | 8.5 | 12 | 7.1 | 75 | 34 | 18 | 2.8 |

| DTL-1-35 | 10.5 | 14 | 8.5 | 85 | 39 | 20.5 | 3 |

| DTL-1-50 | 10.5 | 16 | 9.8 | 90 | 41 | 23 | 3.4 |

| DTL-1-70 | 12.5 | 18 | 11.5 | 102 | 47 | 26 | 3.6 |

| DTL-1-95 | 12.5 | 21 | 13.5 | 112 | 50 | 28 | 4.2 |

| DTL-1-120 | 14.5 | 23 | 15 | 120 | 53 | 30 | 4.8 |

| DTL-1-150 | 14.5 | 25 | 17 | 126 | 55 | 34 | 5.3 |

| DTL-1-185 | 16.5 | 27 | 18.6 | 133 | 57 | 37 | 5.8 |

| DTL-1-240 | 16.5 | 30 | 21.5 | 140 | 60 | 40 | 6 |

| DTL-1-300 | 21 | 34 | 24 | 158 | 66 | 45 | 7 |

| DTL-1-400 | 21 | 38 | 27 | 178 | 76 | 55 | -- |

| DTL-1-500 | 21 | 45 | 30 | 200 | 85 | 60 | -- |

| DTL-1-630 | -- | 50 | 34.2 | 225 | 85 | 80 | -- |

| DTL-1-800 | -- | 60 | 38 | 270 | 90 | 100 | -- |

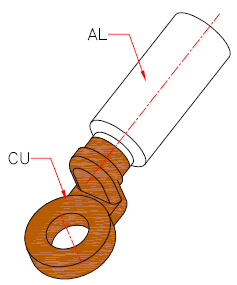

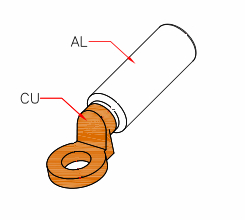

Features:

DTL-2 Cable Bimetallic Lug is suitable for aluminum to copper terminations. Manufactured from high purity copper and aluminum rod and friction welded. And DTL-2 Cable Bimetallic Lug is made of 99.5% purity aluminum and 99.9% purity copper.

Advantages:

1)we can customize products according to your requirements (eg. the size; the logo; the package) if large quantity;

2)Barrels are capped and filled with grease so as to avoid oxidation of the aluminum.

3)The technology of friction welding is wonderfully adopted. Therefore they have distinguishing features of strong weld intensity, good nature in electrification resistant galvanic corrosion and long service life.

Instructions:

DTL-2 Cable Bimetallic Lug is suitable for aluminum to copper terminations.

| Item No. | φ | D | d | W | S | L1 | L |

| DTL-2-10 | 10.5 | 14 | 6.5 | 20 | 2.5 | 42 | 87 |

| DTL-2-16 | 10.5 | 16 | 6.5 | 20 | 2.5 | 42 | 87 |

| DTL-2-25 | 10.5 | 16 | 7.5 | 20 | 3 | 42 | 87 |

| DTL-2-35 | 10.5 | 16 | 8.5 | 20 | 3 | 42 | 87 |

| DTL-2-50 | 12.8 | 20 | 9.8 | 25 | 4 | 43 | 87 |

| DTL-2-70 | 12.8 | 20 | 11.5 | 25 | 4 | 43 | 87 |

| DTL-2-95 | 12.8 | 20 | 13.5 | 25 | 4 | 43 | 87 |

| DTL-2-120 | 12.8 | 25 | 15 | 30 | 5.5 | 60 | 111 |

| DTL-2-150 | 12.8 | 25 | 16.5 | 30 | 5.5 | 60 | 111 |

| DTL-2-185 | 12.8 | 32 | 18.5 | 35 | 6 | 60 | 116 |

| DTL-2-240 | 12.8 | 32 | 21.5 | 35 | 6 | 60 | 116 |

| DTL-2-300 | 12.8 | 34 | 23.5 | 35 | 6 | 72 | 127 |

| DTL-2-400 | 17 | 40 | 26 | 36 | 7 | 93 | 160 |

| DTL-2-500 | 17 | 47 | 29.5 | 36 | 7 | 94 | 200 |

| DTL-2-630 | 17 | 47 | 32.5 | 50 | 9 | 94 | 200 |

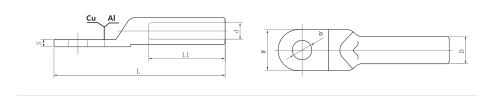

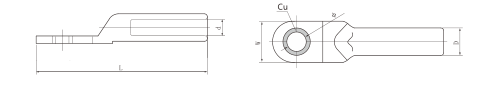

Features:

DTL-3 BIMETALLIC LUG is suitable for screwing non-tension aluminum connections using

Cu-washers in humid areas and for pre-rounded sector shaped conductors. With Cu eye in

screw-on and markings for correct crimping.

Advantages:

1)DTL-3 Bimetallic Lugs come in sizes to fit cables ranging from 35mm up to 240mm, or according to customers’requirements.

2)The technology of friction welding is wonderfully adopted. Therefore they have distinguishing features of strong weld intensity, good nature in electrification resistant galvanic corrosion and long service life.

3)Barrels are capped and filled with grease so as to avoid oxidation of the aluminum.

Instructions:

DTL-3 Bimetallic Lug is suitable for screwing non-tension aluminum connections using Cu-washers in humid areas and for pre-rounded sector shaped conductors.

| Item No. | Dimensions(mm) | ||||||

| C1 | C2 | D | d | φ | L | L1 | |

| DTL-3-35 | 14.5 | 16 | 14 | 8 | 10.5 | 43 | 68 |

| DTL-3-50 | 14.5 | 16.5 | 16 | 10 | 10.5 | 45.5 | 72 |

| DTL-3-70 | 16.5 | 18 | 18 | 11.5 | 13 | 56 | 86 |

| DTL-3-95 | 17.5 | 19 | 22 | 13 | 13 | 57.5 | 90 |

| DTL-3-120 | 16.5 | 19 | 22 | 13 | 13 | 57 | 91 |

| DTL-3-150 | 18.5 | 21.5 | 25 | 13 | 13 | 65 | 103 |

| DTL-3-185 | 22 | 22.5 | 28 | 13 | 13 | 65 | 106 |

| DTL-3-240 | 22.5 | 26 | 32 | 17 | 17 | 69 | 11 |

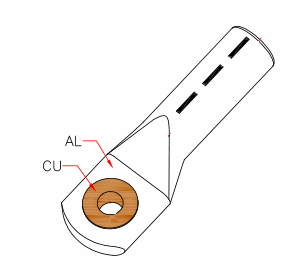

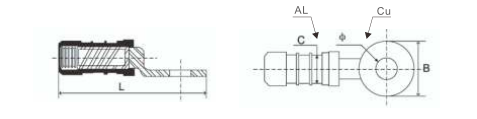

Aluminum inside covered with contact grease for a best electrical contact. A seal-joint allows connecting the copper or aluminum cables. The caps are colored joint to identify quickly the section.

Advantages:

1)These DTL-4 Preinsulated Crimping Lugs for CU or ALU Terminal feature color coded end caps for identification.

2)DTL-4 Preinsulated Crimping Lugs come in sizes to fit cables ranging from 16mm up to 240mm, or according to customers’ requirements.

Instructions:

DTL-4 Preinsulated Crimping Lugs for CU or ALU Terminal are suitable for connecting ABC cables to transformers, switchgear etc. on the pole top.

| Item No. | φ | C | B | L |

| DTL-4 16-10 | 10.5 | 16 | 20 | 75 |

| DTL-4 25-12 | 13 | 16 | 24 | 100 |

| DTL-4 35-12 | 13 | 20 | 24 | 100 |

| DTL-4 50-12 | 13 | 20 | 24 | 100 |

| DTL-4 70-12 | 13 | 20 | 24 | 100 |

| DTL-4 95-12 | 13 | 20 | 24 | 100 |

| DTL-4 120-12 | 13 | 28 | 30 | 118 |

| DTL-4 150-12 | 13 | 28 | 30 | 118 |

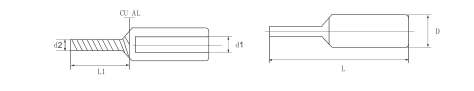

DTL-7 Pin Friction Welded Connector is suitable for screwing non-tension Al connections in Cu clamps. Barrels are capped and filled with grease so as to avoid oxidation of the aluminum and friction welded.

Advantages:

1)Alternative sizes can be made to order for approved order quantities.

2)The technology of friction welding is wonderfully adopted. Therefore they have distinguishing features of strong weld intensity, good nature in electrification resistant galvanic corrosion and long service life.

Instructions:

DTL-7 Pin Friction Welded Connector is suitable for screwing non-tension Al connections in Cu clamps.

| Item No. | d1 | D | d2 | L1 | L |

| DTL-7-16A | 6.3 | 12 | 6 | 20 | 58 |

| DTL-7-25A | 7.1 | 12 | 6 | 20 | 58 |

| DTL-7-35A | 8.5 | 14 | 7 | 22 | 71 |

| DTL-7-50A | 10 | 16 | 8 | 25 | 74 |

| DTL-7-70A | 11.5 | 18 | 10 | 30 | 87 |

| DTL-7-95A | 13.5 | 22 | 12 | 33 | 91 |

| DTL-7-120A | 15 | 23 | 12 | 38 | 98 |

| DTL-7-150A | 18.5 | 25 | 12 | 38 | 108 |

| DTL-7-185A | 19 | 27 | 14 | 40 | 118 |

| DTL-7-240A | 21 | 32 | 16 | 40 | 128 |

GTL BIMETALLIC FRICTION WELDED CONNECTOR is suitable for screwing non-tension Al connections in Cu clamps. Barrels are capped and filled with grease so as to avoid oxidation of the aluminum and friction welded.

Advantages:

1).GTL Bimetallic Friction Welded Connector is suitable for aluminum to copper terminations

2).Friction welded

3).Manufactured from high purity copper and aluminum

4).Prefilled with jointing compound

5).Individually packed in sealed plastic bags

6).fill with grease to avoid oxidation

Instructions:

These Bimetallic Friction Welded Connectors are applicable to connect the circular wire and hemicycle-sector wire in distribution equipment or power supply cables. GTL series hole passing connecting tube is made of frition-welding craft, top quality.

| Item No. | D | d | D1 | d1 | L1 | L2 | L |

| GTL-16 | 10 | 6 | 9 | 5.2 | 30 | 30 | 70 |

| GTL-25 | 12 | 7 | 10 | 6.1 | 33 | 30 | 75 |

| GTL-35 | 14 | 8.5 | 11 | 7.1 | 40 | 30 | 85 |

| GTL-50 | 16 | 9.8 | 13 | 8.5 | 42 | 32 | 95 |

| GTL-70 | 18 | 11.5 | 15 | 9.8 | 50 | 38 | 105 |

| GTL-95 | 21 | 13.5 | 17 | 11.5 | 50 | 40 | 110 |

| GTL-120 | 23 | 15 | 19 | 13.5 | 55 | 42 | 112 |

| GTL-150 | 25 | 17 | 21 | 15 | 55 | 44 | 118 |

| GTL-185 | 27 | 18.5 | 23 | 17 | 60 | 46 | 125 |

| GTL-240 | 30 | 21 | 26 | 18.6 | 60 | 54 | 130 |

| GTL-300 | 34 | 23 | 28 | 21.5 | 65 | 56 | 145 |

| GTL-400 | 38 | 27 | 30 | 24 | 70 | 60 | 155 |

| GTL-500 | 43 | 29 | 34 | 27 | 75 | 65 | 165 |

Our Journey

N.I.U Electric Group started over two decades ago with a vision to transform the electrical industry. From a local business, we've grown into a global leader, driven by our commitment to delivering innovative and reliable electrical solutions.

Quality Commitment

Quality is at our core. Every product is meticulously designed and manufactured in our state-of-the-art facilities, ensuring top-notch standards and durability.

Innovative Solutions

Our R&D team continually explores cutting-edge technologies to create products that set industry benchmarks, enhancing safety and efficiency.

Global Presence

With a strong global network, we cater to diverse market needs, ensuring timely delivery and exceptional service, while staying connected to our local roots.

Sustainability

We prioritize eco-friendly practices and corporate responsibility, striving to minimize our environmental footprint and support community initiatives.

Customer Focus

Our customers are central to our success. We provide tailored solutions, expert support, and a seamless experience to meet their unique needs.

Join us at N.I.U Electric Group and experience excellence in electrical solutions. For more details, visit our website.

FAQ

N.I.U Electric Group is a global leader in providing high-quality electrical products. Founded over two decades ago, we have grown from a local business into an internationally recognized company, dedicated to innovation and excellence in the electrical industry.

We ensure quality through rigorous quality control measures at every stage of production. Our state-of-the-art manufacturing facilities are equipped with advanced technology, and our dedicated team of engineers meticulously designs and tests each product to meet the highest industry standards.

At N.I.U Electric Group, you can purchase a wide range of electrical products including:

Choosing N.I.U Electric Group ensures you receive products of the highest quality, backed by our extensive experience and commitment to customer satisfaction. We offer innovative solutions, a global reach with local impact, and a customer-centric approach that prioritizes your needs. Our focus on sustainability and eco-friendly practices further sets us apart from other suppliers.

We provide a comprehensive range of services including: